Introduction to Catchpit Chambers For Your Drainage System

A catchpit can be installed as part of an underground drainage system to catch sediment and debris that gets carried along the system. A Catchpit Chamber plays an important role in preventing any blockages that if left could lead to flooding.

When to Use a Catchpit?

Catchpits are used to prevent blockages in pipes and stop the backing up of water which could then lead to flooding. They are commonly used in all wastewater management systems - from mainline sewers to the drainage surrounding roads and car parks.

As weather patterns have changed, we've seen more intense rainfall, the more intense rainfalls have led to greater surface water and in turn flash flooding. Catchpit Chambers, therefore, offer a solution to assist with the management of the greater infrastructure of drainage systems that are being built.

Using Catchpits To Control, Contain and Divert

Chambers are essential in any location where the flow of water must be controlled, contained, or diverted and you want to separate silt from surface water ready for removal.

The Water Framework Directive makes silt management an essential consideration in the planning of new highways. Catchpit Chambers, therefore, offer a solution to the issue as simply allowing highway runoff to enter drainage systems is becoming increasingly problematic.

Additionally, like Silt Traps, Catchpit Chambers can also be used upstream from a soakaway system to prevent any debris from entering into the holding tank which would make it inefficient.

How To install Your Catchpit

Catchpits should be set into a minimum 150mm concrete base and then haunched up the side to a minimum of 75mm.

You should also use a minimum of 150mm compacted backfill or granular bedding material around the chamber.

Take a look at our Installation Guide for more detail.

Catchpit Cleaning & Maintenance

It is essential that Catchpit Chamber's are cleaned out regularly. If they aren't then they can fill up with debris which could then flow out the outlet making the chamber useless as debris will continue to flow within the system. In extreme cases, the catchpit chamber itself could also get blocked.

To clean out simply open the catchpit chamber lid before water jetting and vacuumation, using a jet vac tanker. You could even dig out the chamber by hand if space permitted.

How big is a catchpit and how does it work?

Our chambers come in a variety of sizes from 300mm to 1050mm in diameter. They can be used with either 110mm or 160mm EN1401 pipe systems or 150mm, 225mm, 300mm and 400mm twinwall systems.

They come in depths from 750mm to up to 3000mm and all are factory built as single-piece units ready to install - no assembly required.

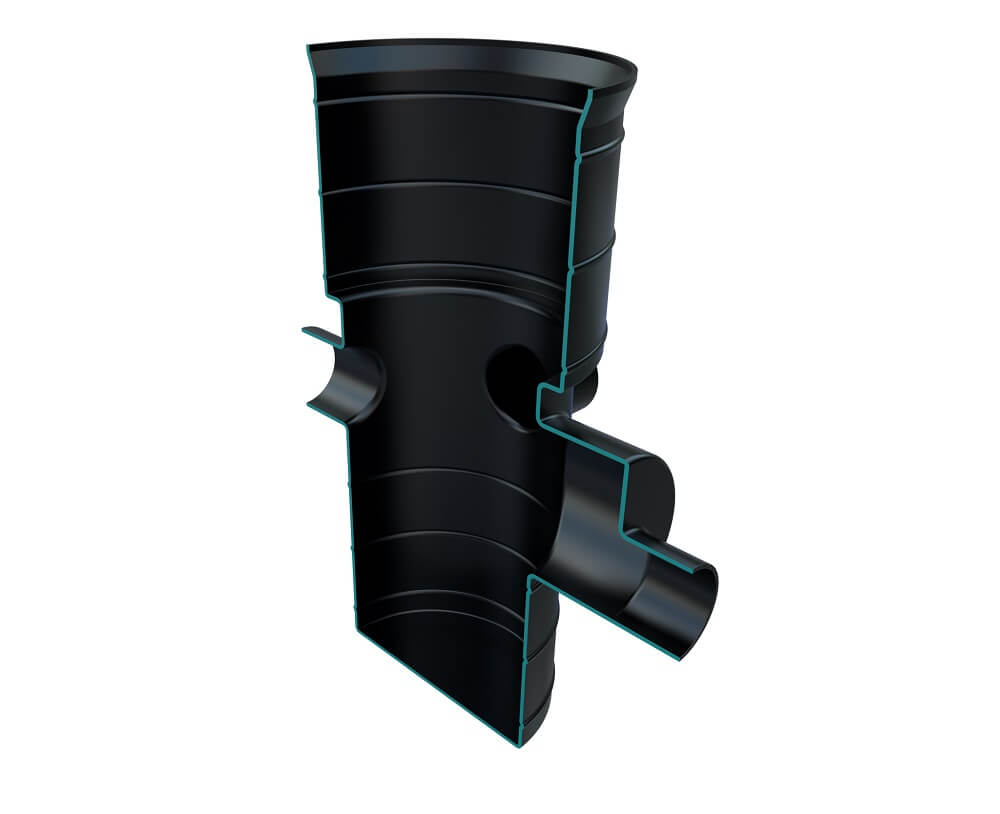

Catchpit Chambers have a raised inlet pipe where surface water enters the chamber. As water flows into the chamber debris and silt then falls to the bottom of the chamber. This area where the silt and debris collects is called the sump (it acts like a well). When the water is high enough above the sump it flows out via the outlet pipe which is lower than the inlet.

| CATCHPIT CHAMBER CUTOUT |

|

What is the difference between a silt trap and catchpit chamber?

Our silt traps include a filtration bucket to separate the silt and debris whereas catchpits include a sump to contain the solids which should be cleaned out with a suction pump or jet vac.